General Instruments Liquid level Gauges

GIC is the leading Liquid level Gauges Manufacturer in India providing reliable solutions for accurate pressure measurement to process industry worldwide.

Liquid Level Gauge provides direct observation of liquid level in a tank / vessel. Rising and falling level of the liquid inside the tank / vessel can be observed through the glass assembled in the gauge. GIC offers liquid level gauges to suit the process requirements. If you notify process conditions i.e. Service, Pressure and Temperature etc., GIC can provide optimum solution to accomplish your process requirements and economy.

- Reflex Level Gauges

- Transparent Level Gauges

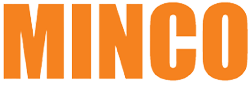

Reflex Level Gauge: In this type of level gauge the liquid level is discriminated in the form of different brightness of the light on the reflex glasses. This is based on refractive indices of liquid and gas or vapor phase. In the liquid phase light is refracted to the glass and absorbed inside the gauge whereas in vapor phase light is reflected against the glass grooves and it appears very bright. This type of gauge is mainly recommended for colourless liquid. The gauge consists of a body machined to have an internal chamber and one or more front windows only on one side of the gauge as shown in figure. On each window a special high resistance plate reflex level glass is fitted with sealing joint and metal covers seized by ‘U’ Bolts and Nuts.

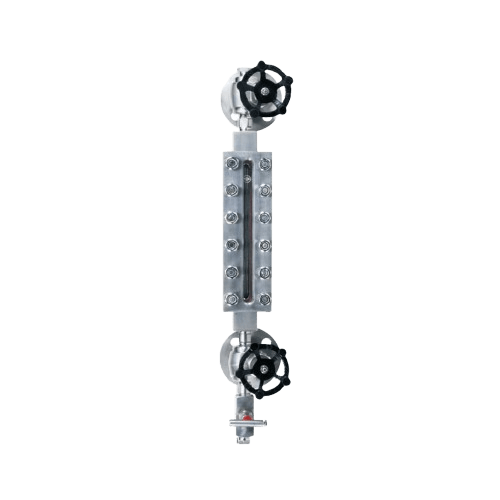

Transparent Level Gauge: In this type of level gauge the liquid level is discriminated in the form of different transparency of the two media. This type of level gauge is mainly recommended for coloured liquids, steam-water and interface liquid level. The gauge consists of a body having machined to have a liquid chamber and one or more windows on both the sides of the gauge as shown in figure. On each window a transparent level glass is tightly pressed with sealing joints between the metallic covers and the body by means of Bolts and Nuts.

Tests:

- PMI Test Bench

- Hydro Test bench Meeting shell Test

- Calibration

- Helium leak Test on Contract

- Radiography Test on Contract

- IBR testing and compatibility

Specifications :

- Type : Reflex / Transparent

- Visibility : Full Visibility / Partial Visibility

- Liquid Chamber : Carbon Steel, SS 304, SS 304L, SS 316, SS 316L, Monel, Titanium, Inconel 600, Hastelloy C, PP, others on request

- Cover Plate : Carbon Steel, SS 304, SS 304L, SS 316, SS 316L, Monel, Titanium, Inconel 600, Hastelloy C, PP, others on request

- Cushion : CAF, PTFE, others on request

- Gasket : CAF, PTFE, Graphoil, others on request

- Toughened Borosilicate : Indigenous – Temperature Range upto 125 C

- Glass : Klinger / Illmadur make or equivalent – Temperature Range upto 320 C as per DIN 7080/7081, BS 3463, Ö-Norm M7353/7354, JIS B 8211, MIL-G-16356D

- Fasteners : SS, ASTM A 193 Gr. B7 / A 194 Gr. 2H

- Isolation Valves : Screwed OR Bolted Bonnet Offset Isolation Valves with Auto Ball Check Arrangement

- Process Connection : From 15 to 50 mm Flanged / Upto 25 mm Screwed / Socket Welded others on request.

- Connection Orientation : Top-Bottom Vertical / Side-Side Right / Side-Side Left / Side-Side Back (Applicable only for Reflex Level Gauge)

- Vent / Drain : ½” Plugged / ½” Needle Valve / ½” Ball Valve, others on request

- Scale : Aluminium / SS engraved in mm.

- Optional : Mica Shields, Non – Frost Extension, Heating Jacket, Illuminators with Die Cast Aluminium Weatherproof to IP – 65 Illuminators with Die Cast Aluminium Weatherproof to IP – 67 Illuminators with Die Cast Aluminium Explosion proof Group IIA, IIB Illuminators with Die Cast Aluminium Explosion proof Group IIC

- Centre to Centre Distance : 175 mm to 3000 mm, others on request

- Operating Pressure : For Reflex – 40 Kg/cm / For Transparent – 30 Kg/cm , others on request

- Operating Temperature : 300 C, others on request