General Instruments Thermocouple assemblies with various coatings on Thermowell for protection

GIC is the leading Thermocouple assemblies with various coatings on Thermowell for protection Manufacturer in India providing reliable solutions for accurate pressure measurement to process industry worldwide.

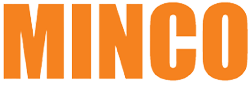

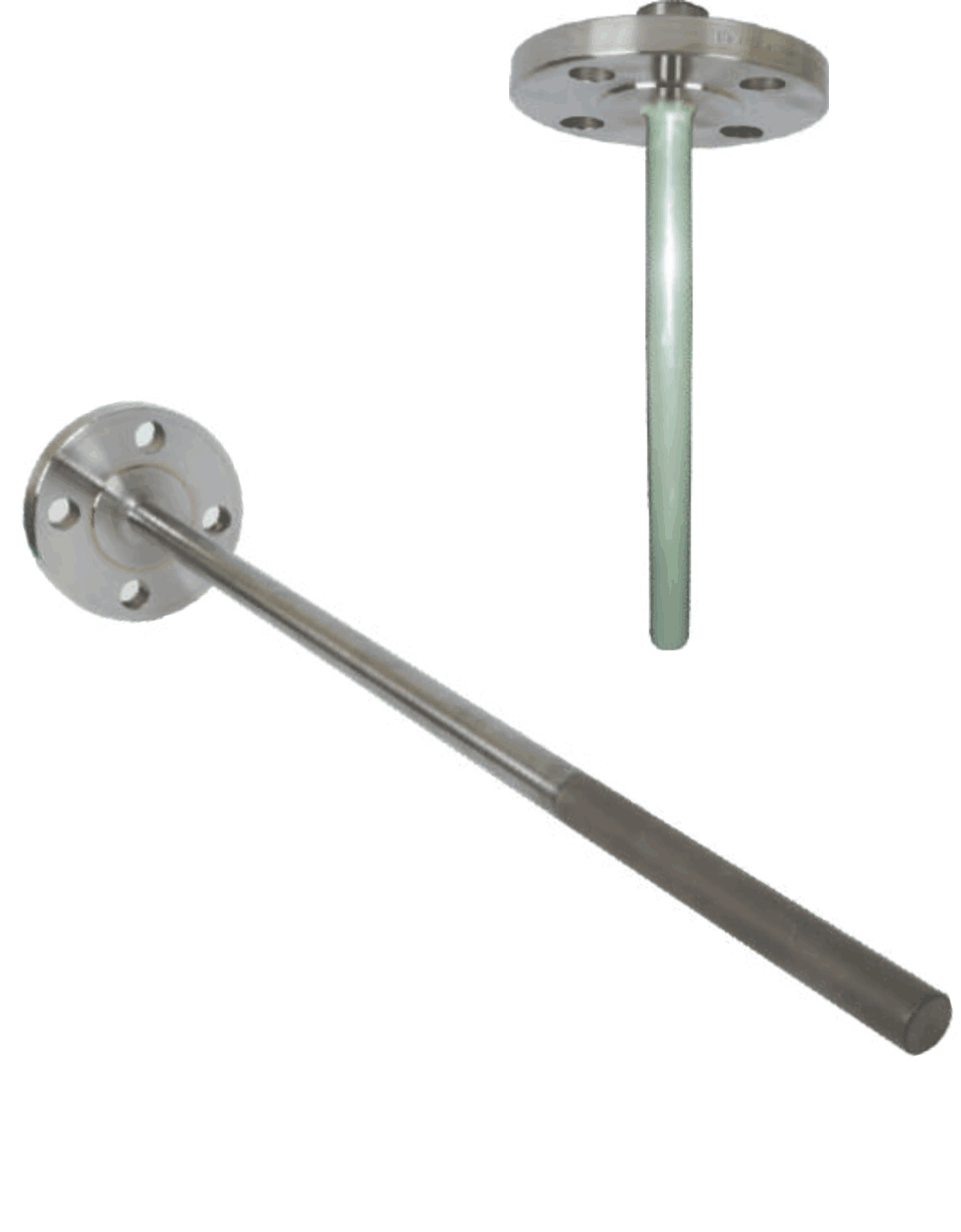

One of the most economical solutions to protect the thermowell from chemically aggressive fluids is to provide a bar-stock flanged thermowell made out of conventional stainless steel with loose lining in the form of a sleeve on the entire wetted portion. This will provide strength from stainless steel & corrosion resistance from the lining.

Routine tests:

a) Accuracy/Calibration Test

b) Nitrogen Leakage Test (Weld

Closure Conformity)

c) Insulation Resistance Test

d) Thermal Response Time Test

e) Continuity Test

f) Dimension Checks

Type tests:

a) Vibration test

b) Drop / Shock test

c) Self-heating error test

d) Hysteresis Test

e) Stability Test

f) Autoclave Test

g) Pull Test (Load Withstand Test)

h) Di-electric strength Test (H.V. Test)

Features:

- Type: Bar-stock flanged

- Well Material: SS316

- Lining Material: Hastelloy® C, Nickel, Titanium, Tantalum, Silver

- Coating Material: PTFE, Alumina, Stellite, TMT (in micron)

- Lining thickness: 0.4 mm for Tantalum & Silver, 1 to 1.5 mm for other materials as standard. Other thicknesses can be provided on request.

- Process Connection: Flanged 1” (DN25) to 3” (DN80) as per ANSI or DIN as standard. Other on request.

- Insertion length: To be specified.

- Note: Sometimes even the conventional stainless steel flanged thermowells can be provided with carbon steel flange corresponding to ASTMA105, with a lining of 3 mm thick stainless steel plate on the RF portion of the flange. This construction offers a very economical solution without having to surrender corrosion resistant characteristics of stainless steels for wetted parts..