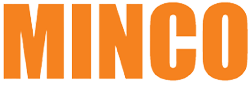

General Instruments Magnetic level gauges & Level Transmitters

GIC is the leading Magnetic level gauges & Level Transmitters Manufacturer in India providing reliable solutions for accurate pressure measurement to process industry worldwide.

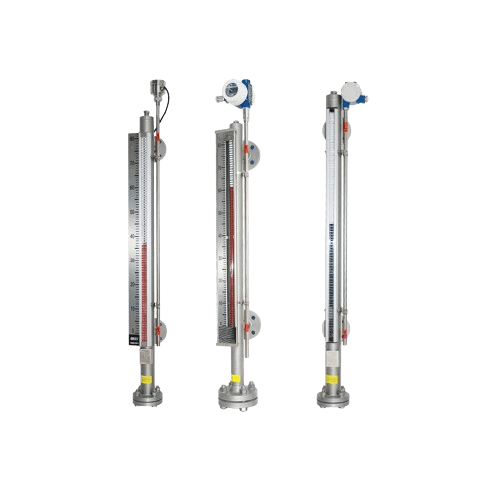

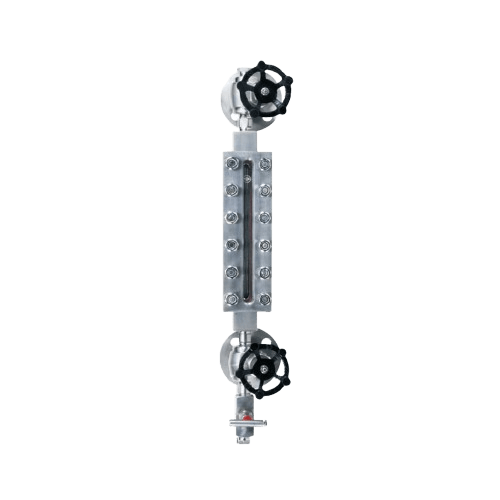

Magnetic Level Gauges provides clear, high clarity indication of liquid level. Magnetic Level Gauges are principally designed as an alternative to glass level gauges. MLGs are now widely used in all industries as they avoid direct contact with indicator system; it eliminates need of glass for direct level indication and prevents chemical spillage due to breakage of glass.

Tests:

- PMI Test Bench

- Hydro Test bench Meeting shell Test

- Calibration

- Helium leak Test on Contract

- Radiography Test on Contract

- IBR testing and compatibility

- Float Test

Specifications :

- Type : Magnetic Level Gauge

- Mounting Orientation : Top Mounted, Side Mounted & Top – Bottom

- Indicator System : Bicolour Rotating Flappers / Capsule Shuttle

- Housing for Indicator : Bicolour Flappers – RAIL in Aluminium or SS Housing

- System : Capsule Shuttle – Heavy Walled Glass Tube in Aluminium / SS Housing

- MOC of Indicators : Bicolour Flappers – Aluminium Capsule Shuttle – Plastic

- Float Chamber : Non Magnetic Standpipe

- MOC of Float Chamber : SS 304, SS 304L, SS 316, SS 316L, Monel, Titanium, Inconel 600, Hastelloy C, PP, PVDF, Other on request

- Float : SS 304, SS 304L, SS 316, SS 316L, Monel, Titanium, Inconel 600, Hastelloy C, PP, PVDF, Others on request

- Process Connection : Flanged in various sizes

- Vent : ½” Plugged / ½” Needle Valve / ½” Ball Valve

- Drain : ½” Plugged / ½” Needle Valve / ½” Ball Valve

- Scale : Aluminium / SS engraved in mm

- Optional : Still Well for Top Mounted Construction

- Limit Switch Assembly : Snap Acting 1 SPDT Microswitch, 5A, 230 VAC

- Switch Housing : Die Cast Aluminium Weatherproof to IP – 65 Die Cast Aluminium Explosion proof suitable for Group IIA, IIB Die Cast Aluminium Explosion proof suitable for Group IIC

- Electrical Cable Entry : ¾”ET(F)

- Centre to Centre Distance : Bicolour Flappers – upto 5000 mm Capsule Shuttle – upto 3000 mm

- Max. Operating Pressure : 25 Kg/cm2 (others on request)

- Max. Operating : For Side Mounted 10 to 80°C / For Top Mounted 10 to 120°C

- Temperature : (others on request)