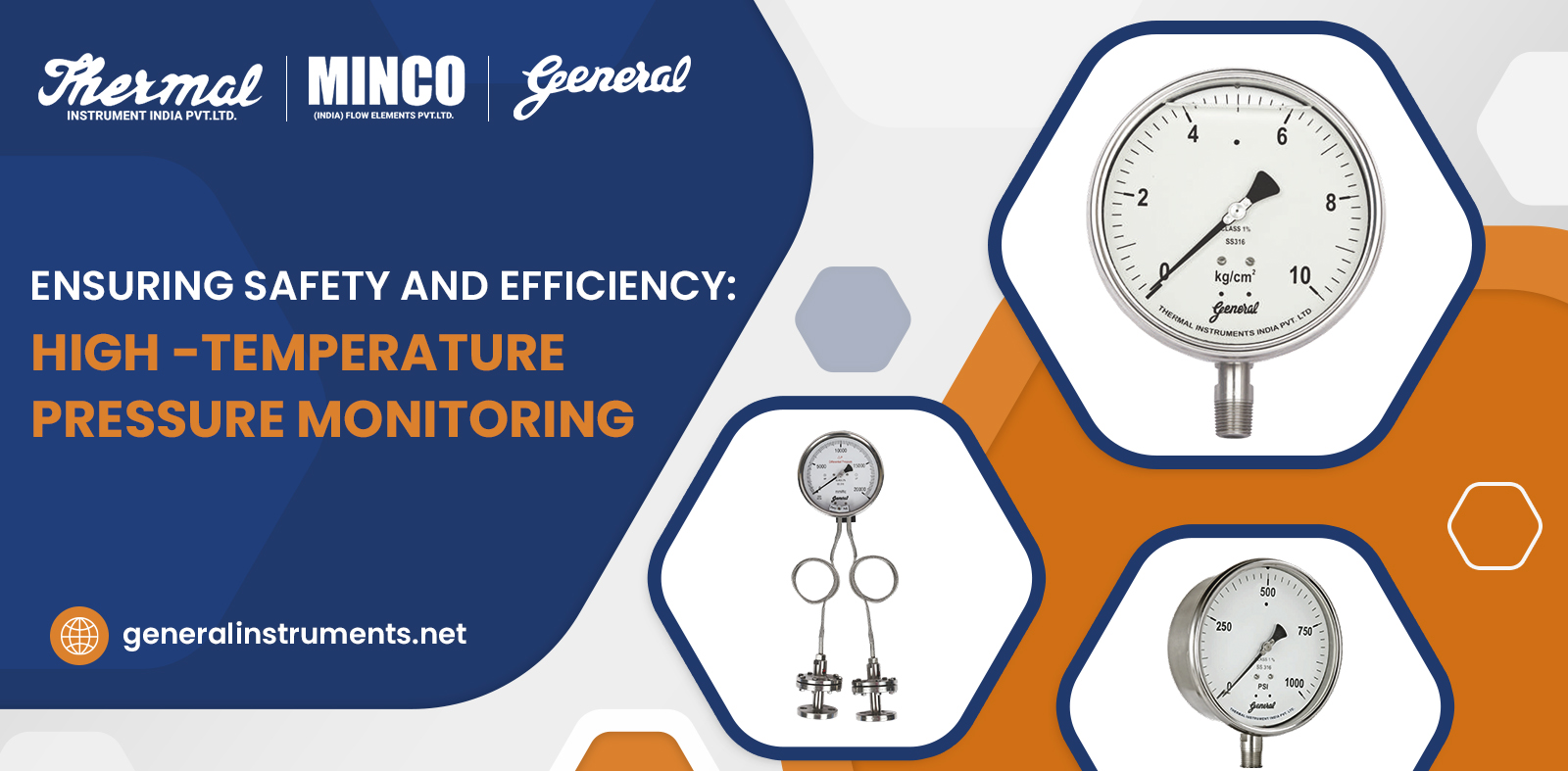

Ensuring Safety and Efficiency: High-Temperature Pressure Monitoring

In many industrial processes, high temperatures are an integral part of operations. From chemical processing to power generation, extreme temperatures are often necessary to drive reactions, generate steam, or achieve desired outcomes. However, these high-temperature environments pose significant challenges when it comes to pressure monitoring, a critical aspect of process control and safety.

The Challenges of High-Temperature Pressure Monitoring:

Material Limitations:

High temperatures can severely limit the choice of materials for pressure sensors and associated components. Many conventional materials may degrade, corrode, or lose their structural integrity when exposed to extreme heat, compromising the accuracy and reliability of pressure measurements.

Thermal Effects:

Temperature fluctuations can introduce errors and drift in pressure readings. Thermal expansion and contraction of materials, as well as changes in fluid properties, can impact the accuracy of pressure measurements, requiring advanced compensation techniques.

Harsh Environments:

High-temperature processes often involve corrosive gases, molten materials, or abrasive particles, subjecting pressure sensors to harsh conditions that can lead to premature failure or inaccurate readings.

Sealing and Isolation:

Maintaining effective sealing and isolation between the process media and the pressure sensor becomes challenging at high temperatures. Leaks or material incompatibilities can compromise the integrity of the pressure measurement system.

Overcoming the Challenges:

To address these challenges, specialized pressure monitoring solutions are required. These may include:

Advanced Materials: Utilizing materials like high-temperature alloys, ceramics, or specialized coatings that can withstand extreme temperatures without compromising performance or accuracy.

Intelligent Compensation: Implementing advanced algorithms and techniques to compensate for thermal effects, ensuring accurate and reliable pressure measurements even in fluctuating temperature conditions.

Robust Sensor Design: Employing ruggedized sensor designs that can withstand harsh environments, including corrosive gases, molten materials, and abrasive particles, while maintaining measurement accuracy.

Effective Sealing and Isolation: Implementing specialized sealing techniques and isolation mechanisms to protect the pressure sensor from direct exposure to the process media while ensuring accurate pressure transmission.

Reliable pressure monitoring in high-temperature environments is crucial for ensuring process safety, optimizing operations, and maintaining product quality. By addressing these challenges through innovative technologies and specialized solutions, industries can overcome the obstacles posed by extreme temperatures and achieve accurate and dependable pressure measurements.

Unlock the full potential of your operations with General Instruments Consortium’s industry-leading process control solutions. We offer a wide range of instruments to ensure optimal efficiency and regulatory compliance.